The introduction:

The emergence of 3D printing technology has granted us a variety of new opportunities in many industries, including oral care. Tailored designs can now be produced for toothbrushes through this strategy, allowing for customization to meet individual preferences and oral care needs. This remarkable development enables us to have personalized toothbrushes that could completely revolutionize the way we look after our mouths. Here, we will examine the benefits of 3D-printed versions, such as diminished waste, enhanced hygiene, and the chance to possess an individual dental health plan.

Customizable Designs:

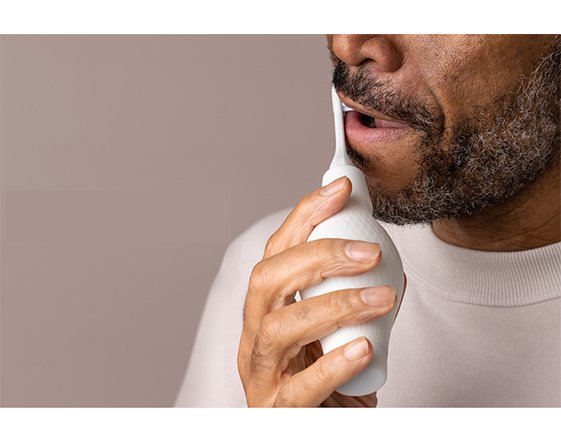

The use of 3D-printed toothbrushes has the potential to offer an excellent brushing experience for individuals. Through customization, features like bristle density, length, and even extra aspects such as gum massagers and tongue cleaners may be precisely tailored to accommodate personal preferences and individual oral health conditions. In comparison to traditional toothbrushes, this technology offers a greater range of options, providing an improved dental hygiene routine.

Tailored Oral Care:

Through 3D-printed toothbrushes, individuals can gain personalized oral care. Dentists and professionals can collaborate with patients to craft brushes that meet their exact needs, like softer bristles for those with sensitive gums or orthodontic appliances necessitating custom designs. Such adaptations increase the efficacy of brushing routines and ensure the best possible hygiene for every customer.

Reduced Waste:

3D printing technology encourages sustainability by minimizing waste in the production of toothbrushes. Instead of mass-producing standardized designs like more traditional methods, 3D printing allows for on-demand fabrication. This significantly cuts down excess inventory and wasted materials. As a bonus, the recyclability and reusability of 3D printing materials further contribute to environmental responsibility. With 3D-printed toothbrushes, it’s possible to reduce the carbon footprint of oral care product manufacturing and move closer to a greener future.

Improved Hygiene:

Maintaining oral hygiene involves more than just brushing; it also involves keeping your toothbrush clean. 3D printing offers a distinct advantage in this regard, as its designs can effectively prevent the growth of bacteria and microorganisms. Traditional toothbrushes have gaps in areas such as where the handle meets the bristles, providing an ideal spot for bacterial buildup. With 3D-printed ones, however, these crevices are eliminated and monolithic designs are created, eliminating potential sites of contamination. This not only contributes to better overall hygiene but also helps reduce cross-contamination between multiple users or in public settings.

Possibilities for the future:

The prospects of 3D-printed toothbrushes stretch far beyond simply customizing designs. As the technology progresses, it is conceivable that sensors and microelectronics could be incorporated into toothbrushes. This could enable instantaneous tracking of brushing techniques, collate data on brushing practices, and deliver tailored advice for higher-quality oral hygiene. The merging of 3D printing and intelligent technology may revolutionize oral healthcare habits and better dental health overall.

In conclusion:

With the advent of 3D-printed toothbrushes, a new era in oral care has begun. With its ability to tailor toothbrushes to individual needs, this innovative technology is changing the way we approach oral hygiene routines by allowing for customized designs, reducing waste, and improving hygiene.